Where the Data Is

/ timeSSD /

Transparency means to not hide the necessary data willingly, nor to forget, it means to provide them in the right time

The idea is by experience form a company in Bangladesh when last year, altogether 11 persons, starting with the CEO, IT manager and down to the line supervisor, we started to search out the cut pieces data of a section for the day before.

It took more than one hour to find out that simple man who had the searched data written with a pencil in a booklet.

Immediately were fired out that simple person. At that moment, near my feelings from the position of a simple observer, an innocent question born in my mind: had that simple person the duty to enter that figures in the integrated management system? Not him, sure, but who from the rest of the 11 persons?

I follow the garment industry from Bangladesh as I have my interests in it and I find out a series of similarities with the years of ’90 in my country, Romania.

The cheap labor and low running costs are an advantage for a time. How this reserve time is used to learn to generate added value? Until when it will be possible to have a high hierarchical structure with managers on all levels and to have missing from the dashboard the simple cutting figure?

A company started to evaluate our software solution dedicated for benchmark execution times and labor costing. After a few weeks, we get the unsatisfactory report because the times aren’t accurate. Sure, it’s part of the game and of the sales to be placed on the second place in a competition. On the request to provide us with the full report, including the comparison tables, we get the answer that our figures were compared with the company Excel-based database, developed by experience.

The question in my mind: why would like somebody to measure the width of a road with micrometer? But in fact, the right question should be: why would like somebody to use a road measurement tool for the buttonhole?

If the resources aren’t tracked and used on their capacity doesn’t matter if the equipment is from China or Japan, is manual or automat, if the IE has a Lean or Kaizen certificate or isn’t certified – for copy – paste is not necessary.

How long time could be allowed to keep tens of industrial engineers which uses old figures for labor costing because is more convenient and easier?

In my opinion, the problem isn’t it in today’s 40% – 45% efficiency level in the line. The missing strategy and will to increase it step by step, day by day is the real gap. Who is in charge with the operator training? How the IE observes and finds out the better, ergonomic, workplace solution if the once acquired PMTS it was only to catch the wanted client and the data from old tables makes the rules?

It’s an effort to find out and convince a good client. It’s another effort to invest in equipment and infrastructure.

Where are the efforts to use the existing capacity to provide the highest results? What happens with the existing human resource in quantity of tens of thousands of hours per day?

Last year we visited a few textile faculties from Dhaka with a demo of the most cost-effective PMTS system dedicated to the apparel industry. Nice reception, many students, good questions during the presentation, restricted group discussions at the end regarding our possible contributions to the educational process, many photos and article in the electronic newspaper of the institute.

During the last months, we sent a few e-mails to start to establish the next steps, unfortunately without any answer. In the meantime we started nice cooperation with faculties from another four countries, two of them never visited. Imminent question: how long does the form last, where does the content begin?

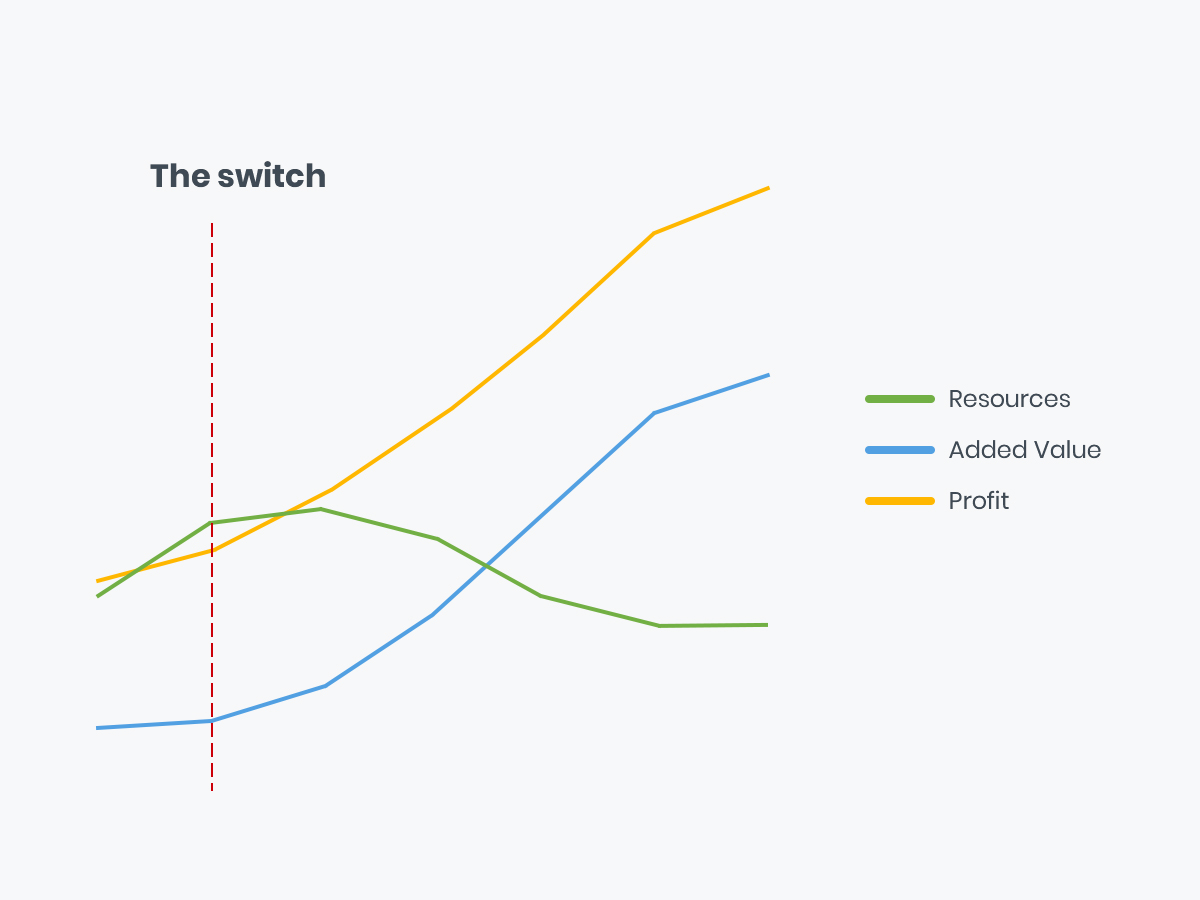

The efforts to make the switch to the next level requires years of investments in the human resources to have delimited clearly the form from the content. Think, search, fight, experiment to provide value instead of tones of forms and titles (less show, more value).

When it will come at that time when the faculties will provide such local professionals which will be able after a few years of practice to take over the jobs from foreign nationals?

Reading on the net I found a respected professional from BD who said that they hold certificates for this, that and that which meant they are transparent. The complaint to the brand they do not follow the transparency because they did not provide their supplier list.

Transparency not mean to publish your latest profit generator secret but means to keep your promises and provide enough data to the party to feel comfortable.

Transparency means to not hide the necessary data willingly, nor to forget, it means to provide them in the right time. The question is immediate: transparency is a certificate or the behavior?

Focus on the content delivered and leave the forms. Have in mind the progress and flexibility and you became by default transparent. The examples from the real life could continue with the questions generated but at the end, all of the questions have the limes at the ‘added value’.